News

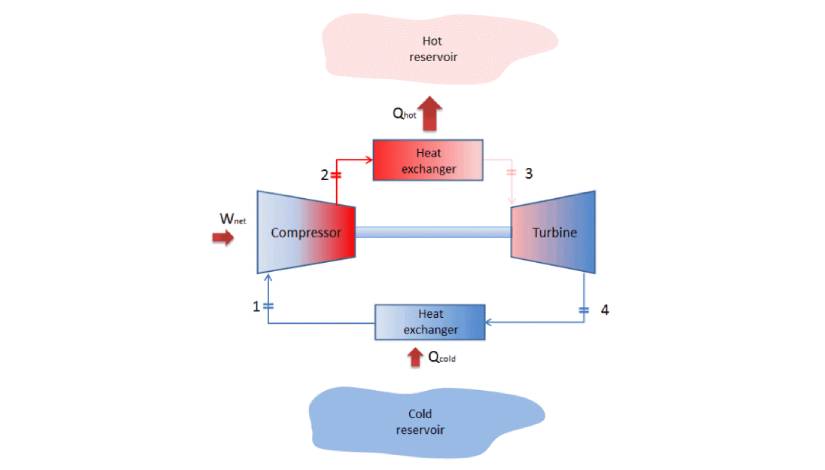

This technology is based on the ability to heat gases (Nitrogen / Helium mixture) during compression in the turbocharger and cool them during the expansion process in the turboexpander. Repeated compression and expansion cycles achieve and maintain ultra-low temperatures.

An essential technological characteristic is that the turbocharger, the engine and the turboexpander are located on the same shaft.

The energy produced during the expansion process is thus transferred through the shaft to the compressor, which significantly reduces energy consumption.

The turbocharger/expander assemblies use magnetic bearings which guarantee five-year maintenance cycles. See our solutions